|

The Story of Multiline Technology

Multiline

is proud to be celebrating its twentieth anniversary this year. The company

which evolved into Multiline Technology, started over sixty years ago

in a 15’ x 60’ small storefront on Gates Avenue in Brooklyn,

New York. In 1936 Hans Lenkeit started a small tool and die company which

carried his name, Lenkeit Machine and Tool Company, which specialized

in precision watch parts. In 1942 all its efforts were devoted to the

manufacture of parts for the military during World War II.

After the war Lenkeit moved to Long Island under the direction of two

skilled tool and die makers, Hans’ son Bill and Fred Angelo (ret.

Chairman) who was the shop foreman. Although the company was now predominately

building compacting dies for the ceramic industry and progressive dies

for metal stamping, Fred Angelo recalls the day a few people came to see

him from a small company on Long Island and asked him to build a die to

punch holes in and blank out a printed circuit board. This small start

up company, Photocircuits, quickly became Lenkeit’s best customer

and soon circuit board dies started to dominate the workload. As the circuit

board industry grew so did Lenkeit’s business and reputation as the

leading manufacturer of PCB dies in the country.

In the mid sixties, under the direction of the company’s President,

Fred Angelo, the company again moved to larger quarters and made some

significant equipment purchases with the first wire EDM (electrical discharge

machining) installed in the area (Long Island) and precision jig grinding

equipment which enabled the tool room to position holes within 0.0001

(one ten thousandth of an inch)of an inch (i.e.; the human hair is approximately

.003” (three thousandths of an inch). This expanded the company’s

capability which was timed perfectly for the next tooling challenge, “Flexcircuits”.

Special flexible circuits which are used for disc reading and similar

applications have stringent requirements on edge quality and can not be

stamped out using conventional steel rule dies. Very tight clearance punch

and dies are necessary to meet these needs. This not only required machining

skills but extensive hand fitting which can only be done by accomplished

tool makers. Fortunately for IBM, Rogers and Buckbee Mears , Lenkeit was

well staffed with these skills. Around this time Lenkeit also started

building lamination plates for its customers who were experimenting with

the relatively new business of laminating multilayers.

In 1978, at the urging of our customers, Lenkeit designed and built the

first Multilayer tooling hole punch , the “Acculine”. Until

the introduction of the Acculine the circuit board manufacturers who were

making multilayers were either drilling in the tooling holes or using

large fixed tooling hole dies in very large punch presses. The advantage

of the Acculine was that it was adjustable from 9” X 9” to 24”

X 24” on ½ inch increments. This was extremely important back

in 1978 since most companies were just getting into the multilayer business

and were not yet standardized on any particular panel sizes.

The most significant contribution of Lenkeit/Multiline at that time was

the introduction of the 4 slot tooling system as a standard for the industry.

The 4 slot system of registration was already being used in the graphic

arts industry with great success. Realizing the need for a tooling system

which would compensate for the poor dimensional stability of artwork and

laminate and also eliminate problems in lay up and drilling, the 4 slot

system was incorporated into the first Acculine and the standard was set.

Today nearly every manufacturer of multilayers throughout the world have

their tooling based around the original 10-D068 print issued for that

first job with 4 -slot configuration.

In late 1979 it became obvious that the growth in the circuit board industry

was going to be in Multilayers. Lenkeit Industries spun off a small machine

building division and called it Multiline Technology. It was not long

before Multiline surpassed the tool and die division in sales. It also

became obvious to management that the skills of the tool makers were better

utilized on the new Multilayer equipment. More products were being introduced,

again at the requests of our fast growing lists of customers, including

Depinners, Lay-Up Stations, Artwork Punches and all types of accessories

needed for lamination. Then in 1984 a major milestone for the new Multiline

Technology occurred, the introduction of the Post Etch Punch.

The Post Etch Punch came about thanks to the persistance of one of Multiline’s

flexible circuit customers who wanted to use the artwork punch to punch

innerlayers. Their reasoning was that the material moved so much that

if they could punch after etching it would greatly improve registration

since material movement would then be compensated for. Recognizing a potentially

good idea, Multiline went to their customers and found that this problem

was even more pronounced in Multilayers due to the stack up of layers

of different constructions. The Optiline PE was born and within a few

years it was the recognized standard in the Multilayer industry for registering

and punching innerlayers.

In the late eighties the need to support our growing list of customers

in Europe dictated the need to start a sales and service organization

there. An area outside of Frankfurt was selected and Multiline International

Europa was started. Today MIE has a staff of thirty people split between

sales, service and customer support.

The next major development for Multiline came with the acquisition of

Loma Park Associates x-ray technology. This was the first x-ray machine

offered which combined the diagnostics of x-ray into a production piece

of printed circuit board equipment. Multiline used its tooling expertise

to transform the somewhat difficult to use Loma Park Optimizer into a

high volume production tool. In 1995 a totally new redesigned x-ray tooling

unit was introduced, the Optiline PL (post lamination drill). Since the

introduction of the OPL we have strived to improve the performance of

these machines and now have through-puts mprove the performance of these

machines and now have through-puts which exceed five panels per minute.

In 1999 the x-ray line of equipment was expanded to include the XRT-1000,

a lower cost slightly slower machine for smaller volume shops.

Multiline Technology’s 20th anniversary was appropriately the best

year in Multiline history. Sales were the highest we have ever had, another

10,000 square feet of manufacturing space was added, and a new very successful

product (glass tooling frames) was launched.

The future of Multiline has and will always be customer service and

satisfaction. It is our overall commitment to listen to our customers

needs and design registration tooling solutions to meet those needs. Working

closely with our customers, Multiline uses Applications Engineering and

R&D resources to develop products that meet both the performance and

the market goals of its customers. We at Multiline Technology look forward

to having the opportunity to be of (continued) service to you and your

company.

|

|

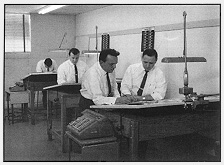

Fred Angelo (Chairman) having discussions

with engineering personnel

|

|

|

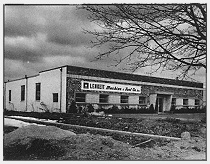

Farmingdale,N.Y. Route 110 location

1964 to 1985 13,000 Square feet

|

|

|

1986 to Present 36,000 Square feet

also located in Farmingdale,N.Y.

|

Home | About Us | Staff | Directions | Products | News | Trade Shows | Literature | Employment | Contact Us

© 2002 Multiline Technology

|