A Safe and Easy Means of Maneuvering Lamination Plates

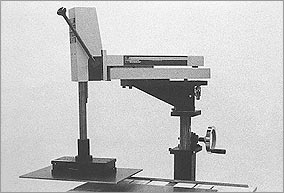

Maneuvering the cumbersome top plate of lamination fixtures becomes a simple task with the Multiline Technology Lamination Plate Handler. Using magnetic force the Lamination Plate Handler mechanically assists an operator in lifting and positioning these plates, making even the largest and heaviest of them weightless.

The Lamination Plate Handler alleviates operator fatigue and injury. Misregistration of boards during lamination is avoided, and damage to lamination fixtures during usage is eliminated. For example, during layup it is commonplace for an operator to experience difficulty while aligning the top plate of a lamination fixture. Pins properly sized for lamination protrude very little from the stacked lamination material, making it difficult for the operator to position the top plate accurately over these pins. Also due to the unwieldy size and weight of top plates, they are often hastily positioned. These conditions frequently result in the top plate being misaligned or skewed. Then, should the top plate be secured with a mallet, or the package be put in the lamination press, pins or bushings may break. This in turn will cause the lamination package to shift.

The Lamination Plate Handler allows the operator to easily pick up the top plate of the lamination fixture, move it out of the way for layup, and move it back into position for alignment. The plate can then be gradually lowered squarely over the lamination pins and secured into position.

The Lamination Plate Handler allows the operator to easily pick up the top plate of the lamination fixture, move it out of the way for layup, and move it back into position for alignment. The plate can then be gradually lowered squarely over the lamination pins and secured into position.

The Lamination Plate Handler utilizes a magnetic chuck to hold the top plate securely in place and a counter-balanced, rack-and-pinion device to amplify an operator's lifting and lowering capabilities. Use of the linear and rotational action of the unit enables an operator to reposition the plate adjacent to, or within 360 of the original position. Then when accurately aligned, the top plate can be released by using a manual lever which reverses the polarity of the magnetic chuck.

The Lamination Plate Handler is constructed on a welded-steel frame and has been designed to be used independently for any general purpose lamination plate handling, or in conjunction with the Multiline Technology Lay-Up Station and the Multiline Technology De-Pinner. Entire pressed packages can be lifted and positioned for depinning with the optional 200 lb. magnetic chuck. The unit comes complete with telescoping legs, leveling feet, and casters. The working height of the unit is adjustable from 32" to 42" making adaptation to existing conveyors and other equipment easy. The Lamination Plate Handler's magnetic chuck is extremely safe to operate and cannot be accidentally disengaged.

The Lamination Plate Handler is constructed on a welded-steel frame and has been designed to be used independently for any general purpose lamination plate handling, or in conjunction with the Multiline Technology Lay-Up Station and the Multiline Technology De-Pinner. Entire pressed packages can be lifted and positioned for depinning with the optional 200 lb. magnetic chuck. The unit comes complete with telescoping legs, leveling feet, and casters. The working height of the unit is adjustable from 32" to 42" making adaptation to existing conveyors and other equipment easy. The Lamination Plate Handler's magnetic chuck is extremely safe to operate and cannot be accidentally disengaged.

Method of Operation

The lifting assembly is positioned over the lay-up area, where the top and bottom lamination plates rest prior to lay-up. The magnetic chuck is lowered into contact with the top lamination plate. The magnet is activated by a lever and the top plate is lifted using a counter-balanced handle and moved to another position. By reversing this sequence, the plate can be positioned and lowered onto the press-ready multilayer stack.

The Lamination Plate Handler is designed to minimize operator fatigue and maximize registration accuracy and safety.

To receive more information on the Lamination Plate Handler through e-mail contact Multiline Technology or fill out our Literature Request Form.