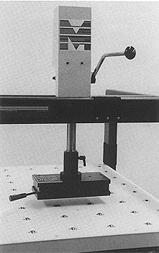

Versatile System Handles Greater Distance in Pin Removal Locations

Multiline Technology's Bridge De-Pinner

easily removes pins from multilayer lamination plates even when edge-to-pin distance is as deep as 15 inches. This versatile unit, built with a special overhead bridge design, will accommodate almost any tooling pin configuration. The Bridge De-Pinner is operated by pneumatic-driven hydraulics which build up pressure until even the most stubborn tooling pins are quietly driven out. This semi-automatic unit helps eliminate damage to expensive lamination fixtures, and offers quiet and efficient high-production usage. Multiline's Breakdown Station is an option which can be integrated into the Bridge De-Pinner. The station effortlessly lifts and removes the heavy top-plate of lamination fixtures after depinning.

Method of Operation

Cumbersome lamination packages are easily moved into place on the Bridge Depinner's roller-ball tabletop. While the packages are being positioned, the Bridge Depinner's knockout pin is retracted, with only a small portion exposed. As a foot pedal is depressed, an air-actuated cylinder exerts light pressure lowering the knockout pin for alignment over the lamination pin. After the pins are aligned, the foot pedal is again depressed to activate the hydraulic cylinder. As pressure from the cylinder increases so does the length of the knockout pin, which indexes forward into the lamination package and drives out the tooling pin.

Cumbersome lamination packages are easily moved into place on the Bridge Depinner's roller-ball tabletop. While the packages are being positioned, the Bridge Depinner's knockout pin is retracted, with only a small portion exposed. As a foot pedal is depressed, an air-actuated cylinder exerts light pressure lowering the knockout pin for alignment over the lamination pin. After the pins are aligned, the foot pedal is again depressed to activate the hydraulic cylinder. As pressure from the cylinder increases so does the length of the knockout pin, which indexes forward into the lamination package and drives out the tooling pin.

Through out its travel, the knockout pin is guided by a sliding, double support system preventing pin bending or breakage, common with conventional depinning.

Through out its travel, the knockout pin is guided by a sliding, double support system preventing pin bending or breakage, common with conventional depinning.

The optional Breakdown Station is designed to minimize operator fatigue and maximize safety. The unit uses a magnetic chuck to lift the top plate of the lamination package after breakdown. As a safety precaution, the magnetic chuck, operated by polarization, cannot become  disengaged even during power failure. It remains firmly in place until the dual-handled safety buttons are depressed, reversing the polarity of the magnet and thereby releasing the plate.

disengaged even during power failure. It remains firmly in place until the dual-handled safety buttons are depressed, reversing the polarity of the magnet and thereby releasing the plate.

The Bridge De-Pinner is mounted on a stand with a laminated table-top surface and stainless steel roller-balls. The unit's safety system has been designed to prevent the De-Pinner from cycling until proximity sensors detect contact between the Plexiglas guard surrounding the knockout pin and the surface of the lamination package. A chute and collection area is provided to gather lamination package. A chute and collection area is provided to gather lamination pins as they are removed. The Bridge De-Pinner comes complete with a knockout pin. 0.025" under the size of the lamination pin used. Additional knockout pins are available.

To receive more information on the Multilayer Bridge De-Pinner through e-mail contact Multiline Technology or fill out our Literature Request Form.