|

The Multiframe is a complete draw replacement style of frame

that easily adapts to existing exposure units. Designed and manufactured

by Multiline Technology in the United States, this new phototool offers

the highest accuracy (± 0.0004") (± 10 µm) in front

to back registration for photo imaging of double sided Printed Wiring

Boards and/or Multilayers. Depending on the tooling system this one frame

can accommodate multiple panel sizes and thicknesses, as well as processing

innerlayers and outerlayers without the need to change the glass.

Unlike typical glass phototools the Multiframe incorporates many

new innovative features. A feature that our customers have expressed excitement

about is the "Spring Loaded Pneumatically Retracted Pin System". This

unique patented pinning system has been developed to ease the removal

of boards (laminated panels) from the tooling pins after exposure. The

pneumatically activated pins are drawn out of the tooling holes by a pneumatic

switch located on the front of the unit. This new pinning system eliminates

prying of boards (laminated panels) from tooling that can cause damage

to the film and the glass.

When is comes to registration, the Multiframe offers a one of

a kind Three-Point Centerline Alignment system. Precision top to bottom

glass registration is achieved by registering the floating top glass to

the bottom glass, by using 3 precision pins that self align to tapered

slots.

A new technologically advanced UV resistant gasket gives this new phototool

flexibility like no others. It automatically adjusts to different panel

thickness ranging from (0 to .1575") (4mm). Without the loss of chamber

vacuum and the need to shim or change over too new seals or hinges.

The Multiframe comes standard with heat strengthened glass and

includes a tool free change over system, which is only offered by Multiline

Technology. This quick-change operation is effortless thus, giving the

operator the ability to change the glass and tooling in minutes.

High productivity and fast setup are common comments from our customers.

This is possible because taping and gluing film is a thing of the past.

Films are held in the top and bottom glass of the Multiframe with

an integrated vacuum system.

Clean room safe bearings are utilized throughout the Multiframe.

Multiline has chosen these bearings because many of our customers expressed

concerns about unwanted metal shavings appearing in exposed films after

prolonged usage. These metal shavings can sometimes get in between panels

and films, which can cause havoc in the quality of your production. Using

a Multiframe produces 100% accuracy and dependable registration

with no metal shavings.

The Multiframe is a complete drawer replacement style of phototool

with interchangeable glass that easily adapts to existing exposure units.

This unit can be utilized for inner/outerlayers as well as solder mask.

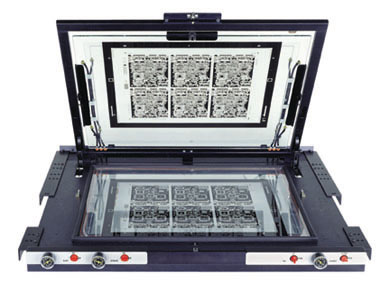

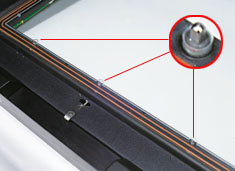

(Front View)

1.Pneumatically Retractable Pin

Multiframe Specifications

Home | About Us | Staff | Directions | Products | News | Trade Shows | Literature | Employment | Contact Us

© 2002 Multiline Technology

|

||||||||||||||||||||||||||||||||||||||

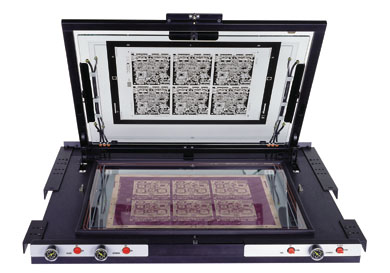

(top view of Multiframe with artwork)

(top view of Multiframe with artwork)

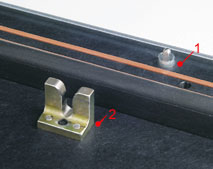

Spring Loaded Pneumatically Retractable Pin System

Spring Loaded Pneumatically Retractable Pin System Side

view of left slot from 3-Point Centerline Alignment System and Pneumatically

retractable Pin System.

Side

view of left slot from 3-Point Centerline Alignment System and Pneumatically

retractable Pin System.