|

| LAMINATION PLATES |

| Class A |

| Parallelism |

+/- .001" |

|

| Thickness |

.275" +/- .002" Or .375"

+/- .002" |

| Flatness Within |

+/- .005"/ft. |

| Edges |

Ground and Rounded |

| Hole toHole

Location |

+/- .001" |

| Finish |

Blanchard and Surface Ground # 32 RMS |

| Bushings |

Precision fit to the thickness

of plate (prevents epoxy buildup) |

| Class B |

| Parallelism |

.002" |

| Thickness |

.275" +/- .002"

Or .375" +/- .002" |

| Flatness Within |

+/- .010"/ft. |

| Edges |

Flame or Saw Cut, Deburred |

| Hole toHole Location |

+/- .001" |

| Finish |

Blanchard Ground # 32 RMS |

| Bushings |

Recessed .010"

below top and bottom surface of plate. |

| Notes: |

| 1 |

All plates available in either stress

relieved H.R.S. or AISI 4140 hardened steel ( Rockwell C 35-40). |

| 2 |

Expansion factor (TCE)" 4140-12.1

x 10-6 per C0 , 1018-11.8 x 10-6

per C0. |

| 3 |

Slot bushings are keyed into position

with a precision ground solid dowel pin. |

| 4 |

All plates marked top and bottom with

set numbers. |

| 5 |

Orientation chamfer available. |

| 6 |

All plates treated with rust preventive,

individually wrapped, and packaged in wooden crates. |

|

STAINLESS STEEL SEPARATOR PLATES

Available in type 304 or type 630 hardened stainless

steel. Type 410 / 420 hardened stainless steel available on request.

|

| Type 304 |

|

|

| Industry standard with sufficient

corrosive and scratch-resistant properties at an economical price. |

|

| Parallelism |

+/- .001" |

| Thickness |

.060" +/- .004" |

| Finish |

#4 |

| Available

in 304 type 630 hardened stainless steel. Type 410 / 420 hardened

stainless steel available on request. |

| |

| Type 630 |

|

|

| Vacuum degassed

and precipitation hardened. The precipitation hardening process insures

that the plate will always remain hard and flat. These plates are

harder, flatter and more corrosive resistant than 410 / 420 martensitic

stainless steel. |

|

| Hardness |

40-50 Rockwell C |

|

| Parallelism |

+/- .001" |

|

| Thickness |

.064" +/- .004" |

|

| Finish |

#4 (12 RMS) |

|

| Chrome Content |

16.5% Approx. |

|

| Nickel Content |

4% Approx. |

|

| Expansion Factor (TCE) |

11 x 10-6 per C0 |

|

| LAMINATION FIXTURE ACCESSORIES |

| Slot Bushings |

New Part No. |

|

| .1875" x .250" ID x .275"

thick |

ZZB01G |

| .1875" x .250" ID x .375"

thick |

ZZB02G |

| .1875" x .250" ID x 10mm thick |

ZZB03G |

| Round Bushings |

New Part No. |

|

| .250" ID x .275" thick |

ZZB11I |

|

| .250" ID x .375" thick |

ZZB12I |

| .250" ID x 10mm thick |

ZZB13I |

| .1875" ID x .275" thick |

ZZB21B |

| .1875" ID x .375" thick |

ZZB22B |

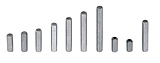

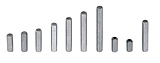

| Lamination Pins |

New Part No. |

|

| Pins used in

lamination fixtures to align multilayers during lamination |

| .1875" x .250" Flatted Round

Pin Lengths: |

|

|

| 3/4" (.750") |

ZZF01J |

|

| 7/8" (.875") |

ZZF02J |

| 1" (1.00") |

ZZF03J |

| 1 1/4" (1.250") |

ZZF04J |

| 1 1/2" (1.500") |

ZZF05J |

| 1 3/4 (1.750") |

ZZF06J |

|

| 2" (2.00") |

ZZF07J |

|

| 5/8" (.625") |

ZZF08J |

|

| 1/2" (.500") |

ZZF09J |

|

| 1 3/8" (1.375") |

ZZF10J |

|

| |

|

|

| .250" Diameter Round Pin Lengths: |

|

|

| 3/4" (.750") |

ZZR01F |

|

| 7/8" (.875") |

ZZR02F |

| 1" (1.00") |

ZZR03F |

| 1 1/4" (1.250") |

ZZR04F |

| 1 1/2" (1.500") |

ZZR05F |

| 1 3/4 (1.750") |

ZZR06F |

|

| 2" (2.00") |

ZZR07F |

|

| 5/8" (.625") |

ZZR08F |

|

| 1/2" (.500") |

ZZR09F |

|

| 1 3/8" (1.375") |

ZZR10F |

|

| |

|

|

| .1875" Diameter Round Pin Lengths: |

|

|

| 3/4" (.750") |

ZZR81D |

|

| 7/8" (.875") |

ZZR82D |

| 1" (1.00") |

ZZR83D |

| 1 1/4" (1.250") |

ZZR84D |

| 1 1/2" (1.500") |

ZZR85D |

| 1 3/4 (1.750") |

ZZR86D |

|

| 2" (2.00") |

ZZR87D |

|

| 5/8" (.625") |

ZZR88D |

|

| 1/2" (.500") |

ZZR89D |

|

| 1 3/8" (1.375") |

ZZR90D |

|

| Tefstops |

New Part No. |

|

(1000/bag)

Teflon washers which fit tightly on

lamination pins

prevent epoxy flow during lamination. |

| .1875" x .250" ID x .500"

OD |

ZZS01A |

|

| .250" ID x .500" OD |

ZZS02A |

| .1875" ID x .375" OD |

ZZS03A |

| |

|

|

Tefstops Coils

(1000/coil qty.)

Teflon washers in continuous coil dispenser with breakaway perforations

for easy application. |

|

| .1875" x .250" ID x .500"

OD |

FW023A |

| .250" ID x .500" OD |

FW024A |

| .1875" ID x .375" OD |

FW028A |

| |

|

|

Knockout Pins

Drive pins used for removal of lamination pins

from fixtures after lamination

|

|

Sure Shot Manual Knockout Pin

For Multiline Semi-Automatic Depinners call for immediate quotation. |

ZZK02B |

|

Cleaning Pads

Non-abrasive polishing pads for surface cleaning of laminaton

fixtures. |

ZZN01A |

|

| FIXTURE CLEANING TOOLS |

| |

New Part No. |

|

Cleaning Brush

For separator plate slots or holes

|

AS323A |

|

| Brush Replacement |

ZZU01A |

|

Insert to fit cleaning brush handle.

Cleaning Broach

For lamination fixtures. |

|

|

| .1875" x .250" slot |

ZZC11A |

|

| .250" round |

ZZC12A |

| .1875" round |

ZZC13A |

Broach Replacement

Insert to fit cleaning broach handle. |

|

|

| .1875" x .250" slot |

ZZC01A |

|

| .250" round |

ZZC03B |

|

| .1875" round |

ZZC02B |

|

| TOOLING PLATE ACCESSORIES |

| |

New Part No. |

|

Delrin Plug

An interchangeable threaded plug for use in

soft tooling locations.

|

ZZD01H |

|

|

Tooling Pins

Pins which are inserted into delrin plugs for

pinning the board to the tooling plate |

|

|

| 1/4" Diameter x 3/4" long |

ZZT01A |

|

| 3/16" Diameter x 3/4" long |

ZZT02A |

1/8" Diameter x 3/4" long

|

ZZT03A |

|

Spanner Wrench

Tool used for delrin plug insertion and removal. |

ZZW02D |

|

|

Torque Wrench

Tool for delrin plug insertion and removal insuring

correct tension to prevent head breakage. |

ZZW01A |

|

|

Pin Setting Gauge

A hardened steel "V" block which insures

precise alignment of the tooling pin into the delrin plug. |

ZZG01A |

|

|

Step Drill and Tap

Special tools designed for machining a counterbored

tapped hole into drilling machine tooling plates to accept delrin

plugs. |

AS915A |

|

| ARTWORK PINS |

| |

New Part No. |

|

Artwork Hat

Metal pins with a wider .375" diameter shoulder

for pinning artwork to laminate during exposure |

|

|

| .1875" x .250" Flatted Round

Pin Lengths: |

|

|

| .040" |

ZZH01D |

|

| .070" |

ZZH02D |

| .110" |

ZZH03D |

| .145" |

ZZH04D |

| |

|

| .250" Diameter Round Pin Lengths: |

|

| .040" |

ZZH11B |

|

| .070" |

ZZH12B |

| .110" |

ZZH13B |

| .145" |

ZZH14B |

| |

|

|

| .1875" Diameter Round Pin Lengths: |

|

| .040" |

ZZH21B |

|

| .070" |

ZZH22B |

| .110" |

ZZH23B |

| .145" |

ZZH24B |

| |

New Part No. |

|

| Exposure Cover Tab |

ZZE01A |

|

UV transparent

tabs which cover the top of the artwork pin during use on the exposure

unit. By protecting the edge of the pin, these tabs help prevent damage

to the vacuum mylar.

|

|

Plating Plug

Prevents electroplating buildup of copper or

solder in slots or holes. |

|

| Slotted Hole |

ZZP01A |

| Round Hole |

ZZP02A |

| |

|

|

Pin Bars

An edge registration tooling bar for use in book printing

exposures which includes three slot tooling to match Multiline edge

tooling configuration at standard 8.095" from centerline. |

| Pin Lengths: |

|

|

| .040" |

AS4089A |

| .070" |

AS4090A |

.170"

|

AS4091A |

| Special sizes available upon

request |

|

|

| BUSHING INSTALLATION KIT |

| All Multiline lamination

fixtures are manufactured with headed bushings which are press fit

into the top and bottom plates. These are used to prevent wear and

maintain size and positional accuracy. Although extreme care is taken

in removing the pins after the lamination process, accidents can happen

resulting in cracking of the hardened bushings. This problem may be

resolved by replacing the damaged bushings; thus prolonging the service

life of your lamination fixtures. Therefore, Multiline Technology

has designed a complete set of tools, installation kit number 30-D249,

which provides an easy and effective method for bushing installation.

The set also includes a standard soft face, dead blow hammer specifically

supplied to prevent denting or scratching the plates' surfaces. |

| Description: |

New Part No. |

|

Complete Kit

Includes: |

ZZB43A |

|

| Bushing Holder |

DS461A |

| Pilot Guide |

DS462A |

| Pilot Drive Punch |

DS463A |

| Head Punch |

DS464A |

| Wooden Spacer |

DW234A |

| V-Block |

DB1430A |

| Drive Pin Punch |

DS465A |

| Soft Face Hammer |

IS001A |

For a complete catalogue on Lamination Fixture Accessories and current

pricing send E-mail to sales@multiline.com

or complete the Literature Request Form.

Home | About Us | Staff | Directions | Products | News | Trade Shows | Literature | Employment | Contact Us

© 2002 Multiline Technology

|